You've heard about the benefits of ICF construction — energy efficiency, strength, durability, quiet interiors — and you're ready to build. But if you've never worked with insulated concrete forms before, where do you start?

This guide walks you through everything you need to know for your first ICF project.

Step 1: Understand What ICF Is

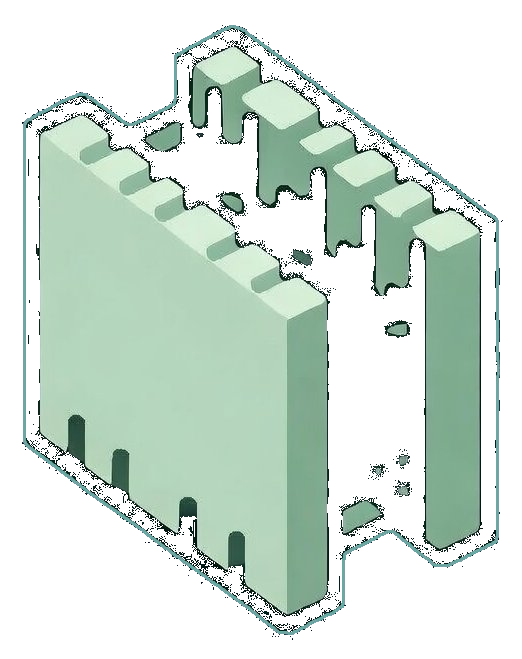

ICF (Insulated Concrete Forms) are hollow foam blocks that stack together like Legos. Once stacked, you fill them with reinforced concrete. The foam stays in place permanently, providing insulation on both sides of the concrete wall.

Key components:

- EPS foam forms — Provide insulation and hold concrete during pour

- Plastic ties/webs — Connect the foam panels and provide attachment points

- Concrete — The structural core (typically 6" for residential)

- Rebar — Steel reinforcement for strength

Step 2: Design Your Project

ICF works with virtually any architectural style, but some designs are more efficient than others:

- Simpler is better — Rectangular footprints use materials more efficiently

- Minimize corners — Each corner requires special forms and more labor

- Plan wall heights — Design to ICF form heights (typically 16" or 18") to minimize cutting

- Window/door placement — Group openings when possible

Pro Tip

Share your plans with us before finalizing. We can suggest design tweaks that save money without compromising your vision.

Step 3: Get a Material Quote

Contact Professional Building Supply with your plans. We'll provide:

- Material takeoff — Exact quantities of each form type needed

- Accessory list — Bracing, window bucks, ties, etc.

- Pricing — Itemized quote for all materials

- Delivery schedule — Coordinated with your construction timeline

Step 4: Get Trained

This is critical. ICF installation isn't complicated, but it's different from wood framing. Proper technique prevents costly mistakes.

Free training is included with qualifying orders from Professional Building Supply. Options include:

- Classroom instruction covering ICF basics

- On-site training during your first project

- Phone/video support during construction

Step 5: Prepare the Foundation

ICF walls typically sit on a concrete foundation or slab. Requirements:

- Level surface (within 1/4" over 10 feet)

- Rebar dowels extending up for wall connection

- Waterproofing/damp-proofing below grade

Step 6: Stack the Forms

ICF stacking is straightforward once you understand the system:

- Set first course on foundation, leveling carefully

- Install rebar per engineering requirements

- Stack subsequent courses, staggering joints

- Install bracing every 4-6 feet

- Cut openings for windows and doors

- Install window/door bucks

Step 7: Pour Concrete

The concrete pour is the most critical phase. Key considerations:

- Use proper concrete mix (typically 3,000-4,000 PSI, 5-6" slump)

- Pour in lifts of 4 feet maximum

- Vibrate to consolidate (but don't over-vibrate)

- Allow proper curing time before removing bracing

Ready to Start Your First ICF Project?

Contact us for a quote and information about our free training program.

Call 512-294-2477Common First-Timer Mistakes to Avoid

- Insufficient bracing — The #1 cause of blowouts. Don't skimp here.

- Pouring too fast — Patience prevents blowouts and cold joints.

- Skipping training — A few hours of instruction saves days of problems.

- Wrong concrete mix — Too wet or too stiff causes issues. Follow specs.

- Inadequate planning — Have all materials on site before starting.